Better revision for a better recovery

Using the new gigli saw explantation method from Stryker, remove a well-fixed hip stem with minimal bone loss every time. Decrease recovery time and increase satisfaction.

Stryker Hip Stem Explantation Device

Designing a better hip stem revision for a faster, fuller recovery.

Overview

Client:

Stryker Orthopaedics

Role:

Team Leader and Corporate Liaison

Duration:

Jan 2019-Mar 2020

Team:

Sabrina Chen, Jess Donaldson, Frank Gesualdo, Abbie Noble, Felipe Torres

My Responsibilities

- Handled Communication with Client

- Interviewed Surgeons

- Designed Presentations

- Created Concept Drawings

- Advocate for Team

Project Research

Why Hip Stem Revision?

Hip stems are designed in such a way that the bone grows into the porous upper section of the implant. This becomes a problem when a well fixed stem needs to be removed due to infection or rejection.

Current methods of hip stem revisions such as the Extended Trochanteric Osteotomy and Steinman Pin Technique are time consuming, unreliable, and often leave the patient with significant bone loss.

Hip Stem anatomy and current removal techniques

Stake Holder Needs

Through interviews with stake holders, we determined the key features that each stake holder required.

Surgeons

- Adds minimal time to surgery

- Seperates ingrown bone from initial stem

- Preserves Bone

- Versatile for use with various stem designs

Hospital Administration

- Cost Effective

- Satisfies surgeons' needs

- Can be used with any hip stem

Insurance Companies

- Minimizes potential recurring costs from additional revisions

Patients

- Preserves bone

- Less invasive than industry standard

- Minimize the risk of future infections and revisions

Contacts: Dr. Ranjan Sachdev, Dr. James Costanzo, Dr. Nitin Goyal, Dr. James Tovey

Problem Statement

Provide surgeons with a repeatable and reliable explantation process to optimize bone preservation and minimize surgical incisions to remove well-fixed, uncemented hip stems.

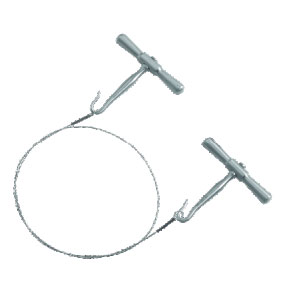

Concept Generation

Our team looked at the separation of the bone from the implant via mechanical, thermal, and chemical energies. Our client steered us toward the mechanical route to make it easier to build a working prototype. After experimenting with a variety of methods. the team decided to move forward with a tool called a gigli saw. This is a thin, flexible wire that can cleanly cut bone by applying alternating upward force to the handles.

- Durable

- Reasonably Priced

- Compact

- Consistent

- Flexible/ Compatible

Gigli saw with handles

Once we decided that we wanted to use the gigli saw in our design, we began developing concept ideas of how to apply it. We created concept drawings and shared them with stakeholders for feedback. Surgeons were excited by our design, and so we started creating our first prototypes

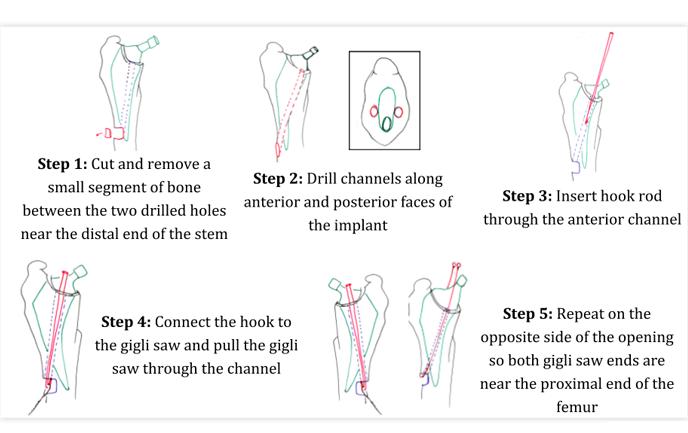

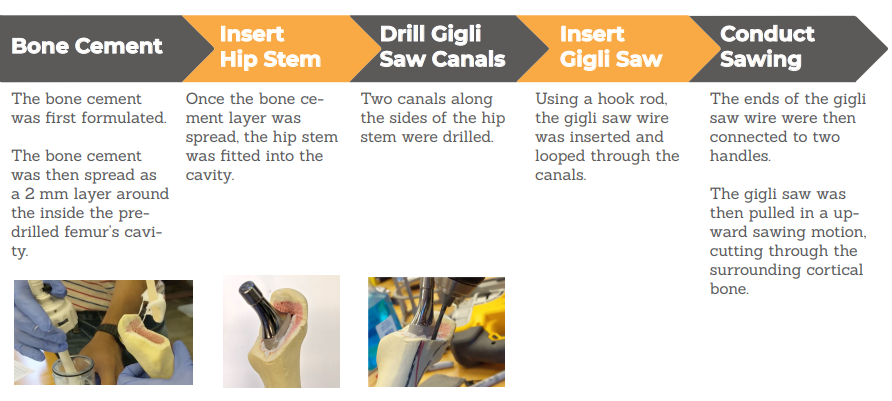

Prototype and Test

Next the team began testing our procedure with sawbones. With each test, we began to understand more clearly what worked and what didn’t. We continued to communicate with surgeons about our progress and they helped us to iterate on our designs

Test Procedure

Failure Modes

Final Concept

Finally, after months of testing, we arrived at the right combination of drill bit, drill angle, wire, and handles. We called this procedure GWHIP, an accronym for Gigli Wire Hip Procedure. We presented the procedure to Stryker and they filed for a patent on our design